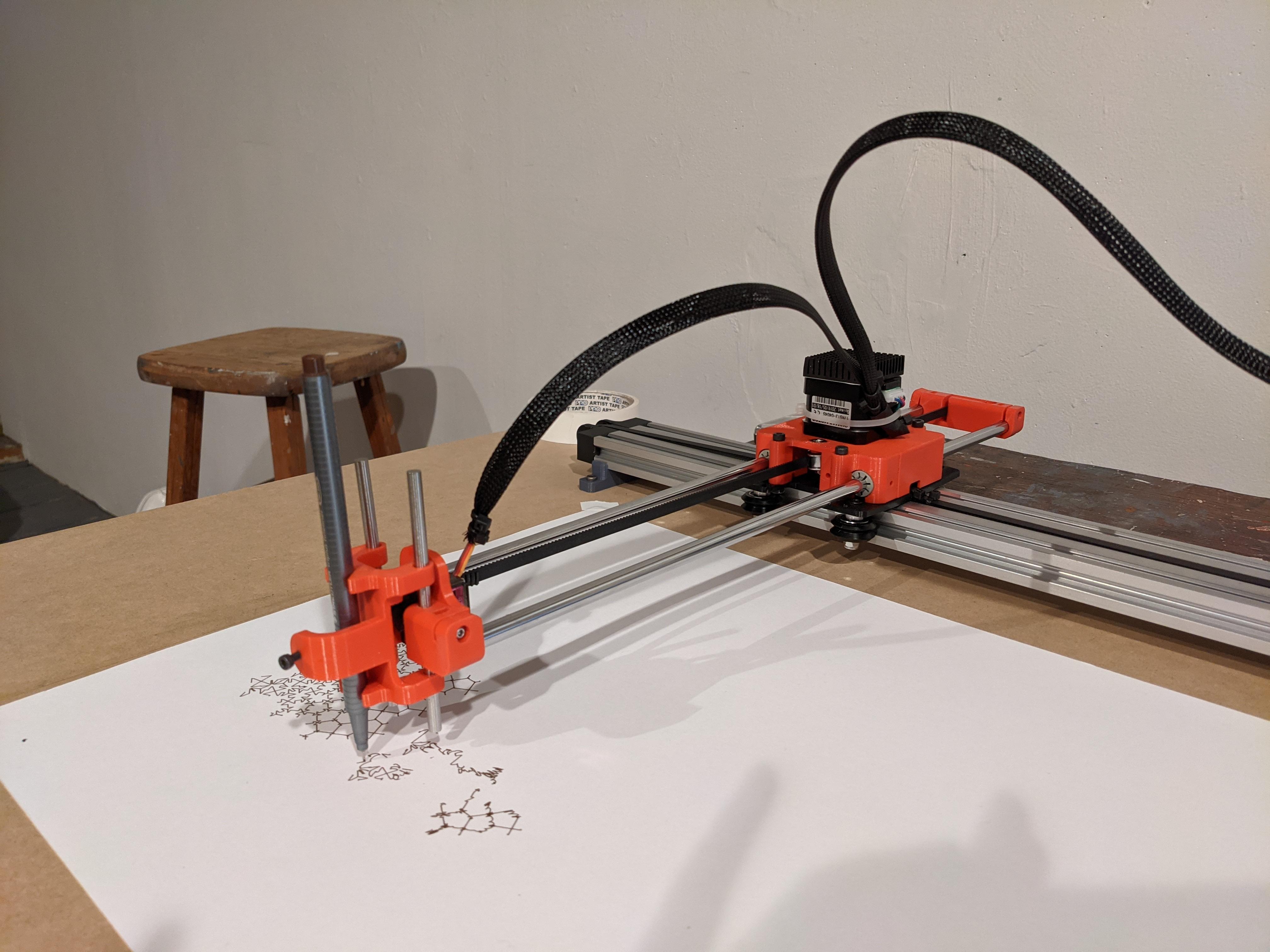

If a one looses steps on my machines, there was a different problem somewhere else before (extruder cooled / broken, part coming releasing from the bed etc.). In the end, for me a stepper loosing steps is simply to flimsy for the application. loosing steps) but the error still happens and still can cause inaccuracy of the parts etc. Closed loop on a stepper does save the job in that it can correct an error (i.e. Closed loop control of the absolute position of the axis (like the big heavy milling machines do) can help with some wobble but i have not yet seen that on a 3D printer.Ĭlosed loop is important for the big machines where you would like to use DC motors instead of steppers (as their power to weight ratio is much better than steppes). Closed loop control of the motor position does not help at all (it only can avoid loosing steps). Wobble occurs because of the frame being not rigid enough, bent leadscrews, pulley bores not centered / to big for the axle etc. Posted in 3d Printer hacks Tagged 3d printing, cnc, core xy, CoreXY, plotting Post navigationĬlosed loop does usually not help with wobble. We’ve also compared the mechanism to the similar H-Bot design. We have looked at a few machines that use core XY before. Controlling these printers takes a little extra math, although the math of a core XY mechanism isn’t all that tricky. The video also talks about some other mechanisms, including delta printers. There’s no perfect world and every choice you make will change the design of your machine in some way. There’s some distinct advantages to doing things this way, but - of course - also some trade offs. That means you have to move both motors to go in a straight line. The belts are arranged so that motion of one motor causes the tool to move at a 45 degree angle. As one end of the belt gets shorter the other end gets longer. You can think of it as an object held by two ends of the same belt. The idea behind Core XY goes back to at least old drafting tables.

has a video (see below) that explains how two stationary motors can move a tool anywhere in an XY region.

This is similar to the H-Bot technique, but with some differences. It is interesting because both motors remain stationary and the business end moves entirely on belts or cords. However, one of the oldest means of doing this is the Core XY method. There are many ways to accomplish this, for example, some printers move the tool in the X direction and the bed in the Y direction while others move the entire X carriage in the Y direction and yet more use a delta mechanism. If you are building a CNC machine, a 3D printer, or even a plotter, you have a need for motion in both the X and Y directions.

0 kommentar(er)

0 kommentar(er)